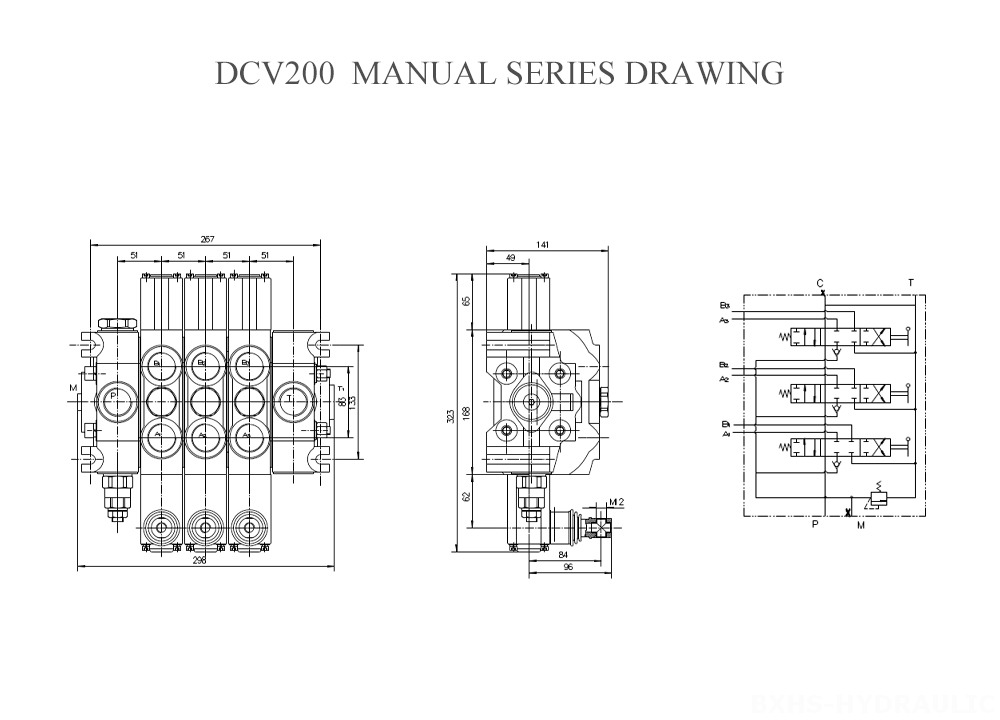

Product name:Hydraulic Sectional directional valve DCV200 series

Brand : ONEDERFUL®

Model : DCV200

sections : 1-12

Certificate: ISO9001-2008

Origin : China

Transportation : By sea / Air DHL / UPS / TNT / Fedex

Payment : T/T transfer Western Union PayPal L/C

| Control Method | manual |

| Presure Medium | Mineral oil based hydraulic oil |

| Nominal Flow | 200 L/min |

| Viscosity Range | 12 CST-400 CST |

| Operating Pressure | 350 bar (35 MPa) |

| Internal Leakage | 15 cc/min at 160 bar, 50℃ |

| Ambient Temp | -40°C to +80°C (-40°F to +176°F) |

| Valve Structure | Sectional Valve |

| Valve Surface | Phosphating treating |

| Valve Sections | 1-12 Sections |

| Rustproof Level | Neutral salt spray test, 48hours |

DCV200 is a hydraulic sectional directional control valve designed for managing hydraulic fluid flow in various industrial and mobile applications. It is part of a series of sectional valves, which are known for their modular design and flexibility.

The company pursues the concept of “continuous innovation, the pursuit of first-class”, and is willing to provide domestic and foreign customers with high-quality products and satisfactory service.