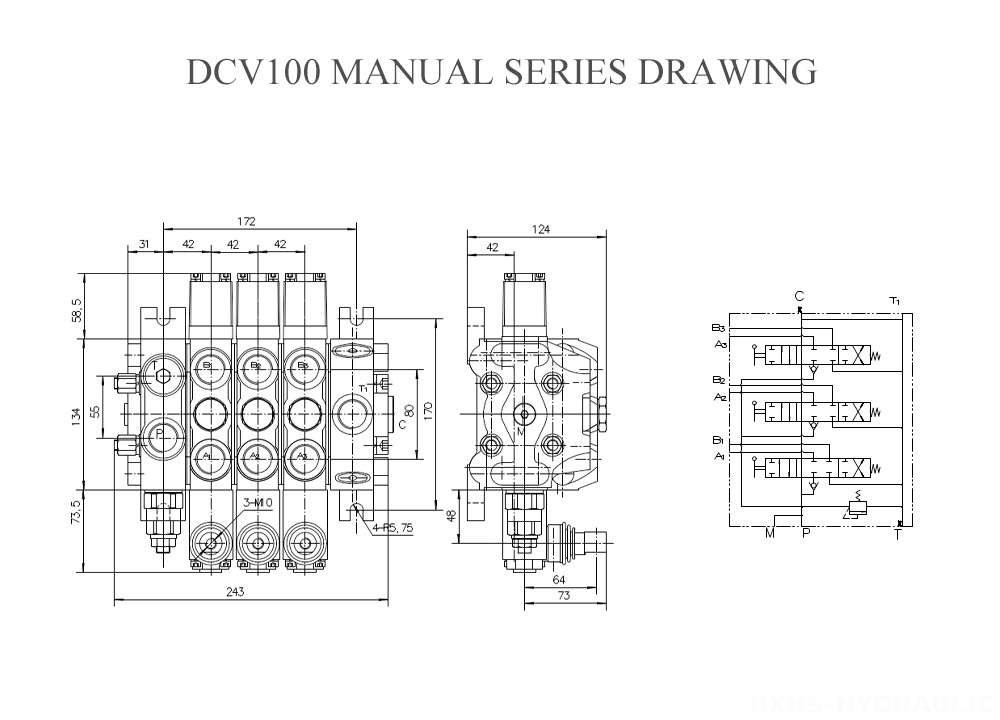

Product name:Hydraulic Sectional directional valve DCV100 series

Brand : ONEDERFUL®

Model : DCV100

sections : 1-12

Certificate: ISO9001-2008

Origin : China

Transportation : By sea / Air DHL / UPS / TNT / Fedex

Payment : T/T transfer Western Union PayPal L/C

| Control Method | manual |

| Presure Medium | Mineral oil based hydraulic oil |

| Nominal Flow | 100 L/min |

| Viscosity Range | 12 CST-400 CST |

| Operating Pressure | 350 bar (35 MPa) |

| Internal Leakage | 15 cc/min at 160 bar, 50℃ |

| Ambient Temp | -40°C to +80°C (-40°F to +176°F) |

| Valve Structure | Sectional Valve |

| Valve Surface | Phosphating treating |

| Valve Sections | 1-12 Sections |

| Rustproof Level | Neutral salt spray test, 48hours |

The DCV100 is a specific model of hydraulic sectional directional control valve, often associated with brands like Parker or similar manufacturers. This model is designed for applications where modular and versatile hydraulic control is needed.

The company pursues the concept of “continuous innovation, the pursuit of first-class”, and is willing to provide domestic and foreign customers with high-quality products and satisfactory service.